These companies believe in our products

Heatech sells heaters, tanks and related products for a wide variety of industries. Our heaters are used mainly for heating liquids and gases. Our tanks are used mainly for mixing and storing liquids. We offer replacement parts and field support for our products and similar products.

To learn more about our products click on the headings shown under PRODUCTS in the top menu.

Additional information for many of these products is contained in our literature. Please click on LITERATURE to see a listing of the literature and to access PDF copies.

We also provide products and technical services for construction and expansion of asphalt and emulsion terminals. For additional information on these topics click on TERMINALS in the top menu.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. In lobortis massa a nibh efficitur iaculis. Nunc ullamcorper, lorem quis dapibus placerat, diam nulla consectetur nunc, vitae maximus orci elit a velit.

WHAT WE DO

All rights reserved HTH Heatech Inc.

HTH Heatech Inc. 61 Industry Way S.E. Calgary, Alberta, Canada, T3S 0A2

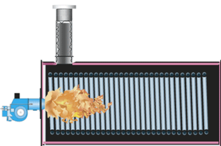

The work horse of our heat medium packages is a helical coil heater. We have been using this design for over 25 years, with proven reliability and quality. There are obvious advantages of this type of heater over other designs. The helical coil offers superior resistance to thermal shock, accepts a wide temperature differential in access of 200oF (93oC), always use at least A-106 Gr B pipe, not tubing and are designed to ASME codes. The heaters come in two configurations, horizontal or vertical, two pass or three pass with efficiencies up to 85%. The helical coil design is ideally suited for glycol, hot oil or as a regent gas heater.

Helical Coil Heaters

Two pass vs three pass design

The two pass design has one coil inside a shell that contains the flue gases. The combustion gases pass through the inside of the coil to the outside and through the stack.

The three pass heater has two coils, one inside the other. The combustion gases pass around the two coils and then to the outside through the stack. Both heaters have their advantages that should be considered when making a choice. We can provide recommendations based on your process needs.

There are several factors that should be considered when evaluating and choosing a thermal fluid heater. A well designed heater will last 20 to 25 years without the need for coil replacement. When choosing a helical coil heater buyers should pay special attention to radiant heat flux rates, combustion loading and radiant surface area. Higher radiant flux rates and combustion loading will produce higher coil surface temperatures that contribute to shorter coil life.

Design considerations